Our Visit to the MINI Oxford Plant

Last week we visited the MINI Plant in Oxford for the Association of Industrial Laser Users (AILU) annual job shop business meeting.

The AILU is an organisation run by the laser community, including members from industrial laser-using companies, academics, manufacturers and suppliers of laser-related equipment or services.

Our Managing Director Neil Main and Operations Manager Chris Waters are both committee members of the job shop subgroup for the AILU and along with Dave MacLellan, the association’s Executive Director, put this annual meeting together.

As industrial laser users, it’s vital for us to play a part in the job shop group to keep up to date on all industry topics and to keep improving the laser technology and processes that we use.

The organisation has been going for nearly 25 years and has such a wide range of laser users involved, from those developing new lasers and new processes to businesses using lasers for customer solutions as we do.

We were joined at this year’s meeting by some of the leading businesses in the laser community, including Essex Laser, Cost Care and Oakwell Management.

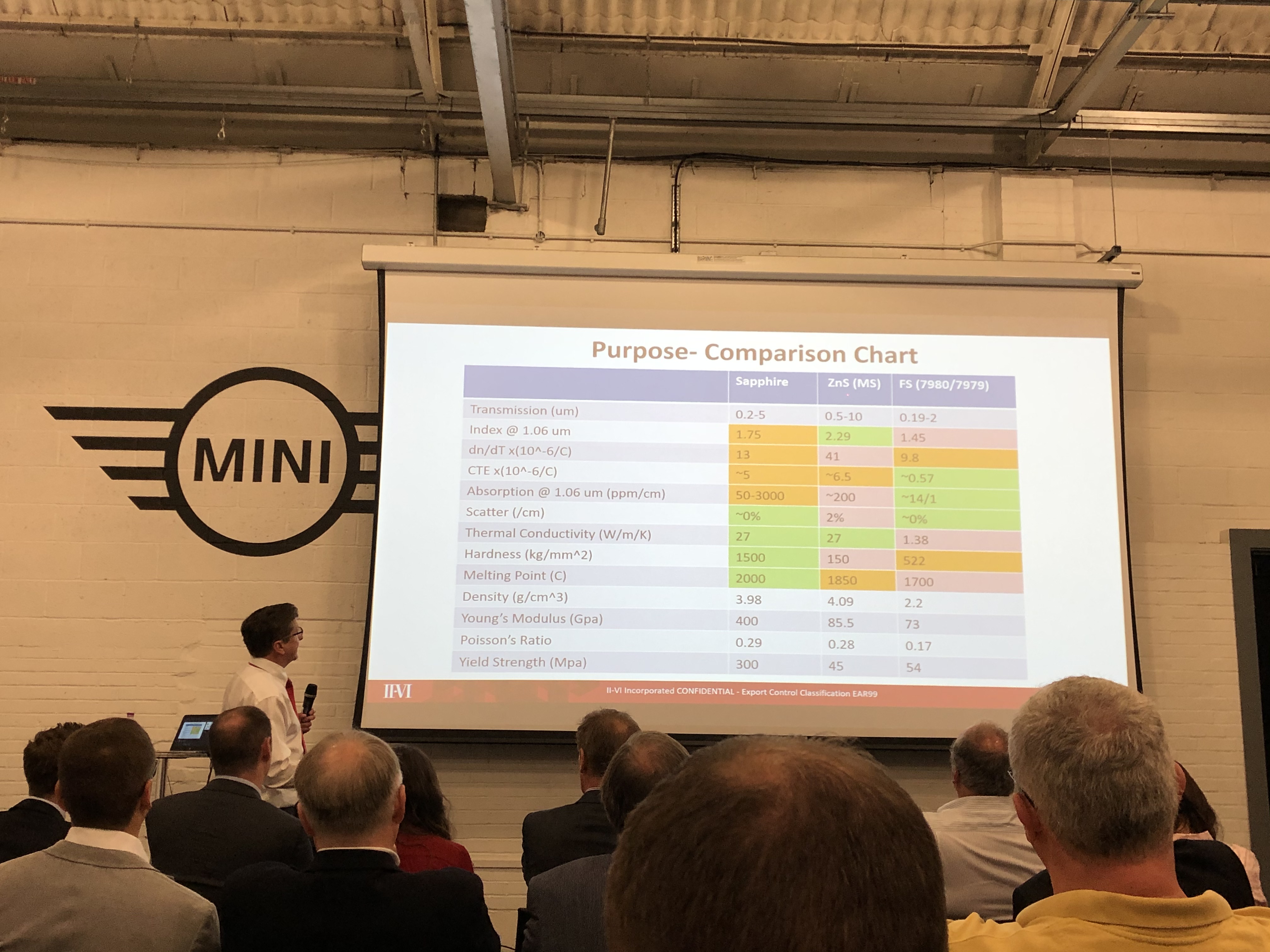

The day itself was filled with several inspiring discussion sessions. These covered some of the biggest trending topics in our industry, including talks on optics for the latest lasers, maximising R&D tax claims and a fantastic talk from Dave MacLellan on reshoring – a hot political topic about ways to get businesses to bring work back to the UK.

We also got involved in the open forum where the topic of choice was (of course) Brexit. Neil contributed by talking about Economic Operators Registration and Identification numbers (EORI) and how to get them for importing or export of goods into or out of the EU. He also talked about their use for individual jobs rather than continuous production, which is useful for other businesses producing smaller batch sizes as we do.

The whole day was full of valuable insights for us to take forward into our work and AILU events are always mutually beneficial for all involved. We found it especially useful to gain knowledge from businesses tackling a wider range of cost cutting than we do, and we assisted other businesses with our expert advice on R&D tax credits and exporting.

We finished our day with a tour around the factory where MINIs are made. This was absolutely amazing, and not just because we are car lovers: we were also able to see the number of robots and the variety and versatility of the production line at MINI. We have been members of the AILU from the beginning and are proud to be contributing to the great events they create. We have seen the benefits of membership again and again and we look forward to continuing alongside some the leading businesses in our industry.