Precision Manufacturing: Wire Erosion and Laser Welding for High-Accuracy Components

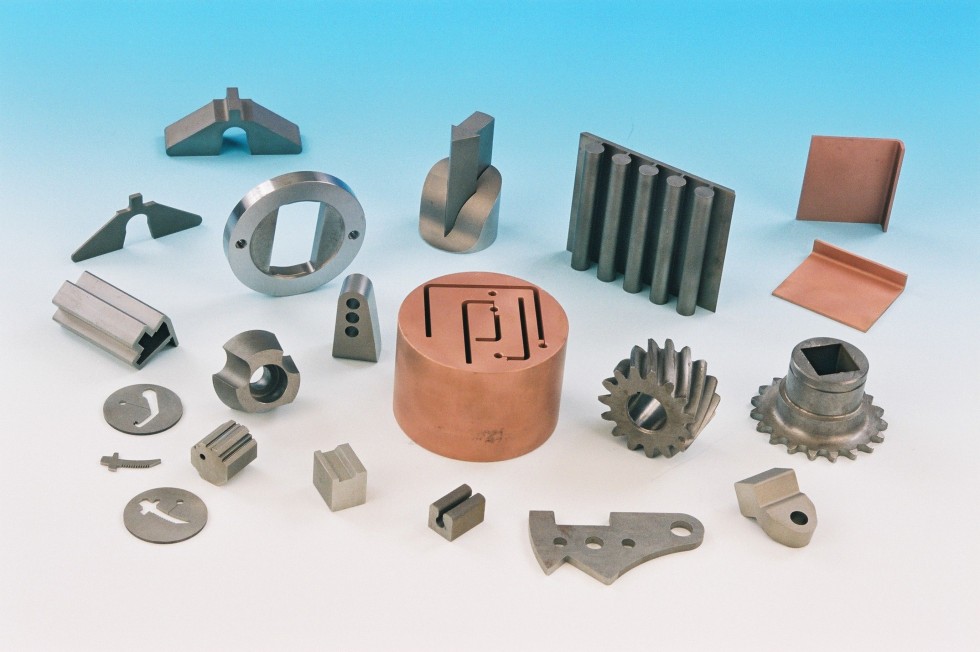

At Micrometric, we specialise in precision engineering techniques that deliver exceptional accuracy and quality for complex components. Two of our key capabilities, wire erosion (EDM) and laser welding, enable us to work with intricate designs, tight tolerances and challenging materials across industries such as aerospace, medical, energy and instrumentation.

Wire erosion: precision without compromise

Wire erosion, or wire EDM (Electrical Discharge Machining), is one of the most precise cutting processes available. It uses a thin wire, charged with electrical current, to erode material along a programmed path. Unlike conventional machining, there’s no direct contact between the tool and the workpiece meaning no mechanical stress or deformation.

This makes wire erosion ideal for:

- Producing fine details, sharp internal corners and intricate geometries

- Cutting hard or exotic materials such as tungsten, titanium and Inconel

- Maintaining dimensional accuracy on small or delicate parts

At Micrometric, our advanced EDM equipment allows us to achieve extremely fine surface finishes and micron-level tolerances, supporting everything from prototype development to full production runs.

Combining wire erosion with laser cutting

By combining wire erosion with laser cutting, we can offer a cost-effective solution for producing parts that have highly precise features.

Laser cutting allows us to cut blanks quickly, minimising production time and material waste. We can then use our wire eroder to finish off the highly precise features ensuring the final component meets the tightest tolerances.

This hybrid approach not only provides the best of both technologies but can also lead to significant cost savings in material and tooling (wire or machine tools), especially when compared to more traditional machining processes.

Laser welding: precision joining with minimal heat

In addition to wire erosion, we offer laser welding services designed for precision assembly work. Laser welding provides the benefit of joining components while minimising heat input, which is critical when welding parts containing temperature-sensitive elements or when avoiding distortion due to heat is essential.

We can perform autogenous welds or welds with wire feed, depending on the component’s requirements. Using wire feed gives us the flexibility to introduce different alloys fine-tuning the weldability and final material properties.

The wire feed system can be fully automated within the welding machine, ensuring consistent and repeatable results across batches. Some materials, such as titanium, require an inert atmosphere so we use an enclosed argon welding system.

Combining technologies for complex assemblies

By combining wire erosion and laser welding, we offer a complete solution for manufacturing and assembly of precision components. Parts can be wire-cut to exact dimensions, then laser welded with minimal heat distortion - an approach that ensures both geometric accuracy and material integrity.

Whether you need intricate metal parts, fine-featured components or assemblies that demand the utmost precision, our integrated processes deliver results that meet the highest technical standards.

We offer a range of in-house and resourced services to complement our laser machining services and we have dedicated equipment for laser drilling, cutting, etching and welding applications. Our extensive work of sub-contracting means that we able to offer a single point of contact for manufacturing parts from the initial process through to completion, helping to reduce lead times and production costs.

We also offer micro laser cutting capabilities that allow small parts to be cut to tight tolerances (+/-0.05mm to +/-0.02mm) across a variety of materials including stainless steel, titanium, copper, brass and ceramic. The smallest part we have produced was a washer with a diameter of 0.5mm. Additionally, we are adept at cutting extremely thin materials down to 0.05mm thickness, which is about three times thicker than household kitchen foil.

We are members of the Midlands Aerospace Alliance (MAA), The Manufacturers’ Organisation (MAKE UK), Association of Industrial Laser Users (AILU) and the Motorsport Industry Association (MIA).

To discover more about our services please contact our team here